Ensuring the Highest Quality and Safest Oilfield Rental Equipment

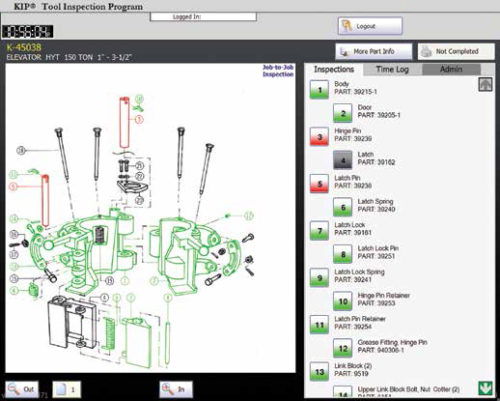

Knight Energy Services’ unique Quality Management System ensures every tool has been tested and every employee is adequately trained to use those tools for oil and gas projects.

The Quality Management System (QMS) defines the direction of Knight Energy Services in the marketplace and benchmarks the most successful business models. It provides a real-time measurement system to evaluate the efficiency and effectiveness of all work processes; this eliminates the guesswork and gives Knight Energy Services the ability to effectively manage our company.

Consistent commitment to the QMS guides our personnel to be constantly aware of providing you with quality equipment and unparalleled service.